ISO 9001 Generic process

ISO 9001 is an international standard for quality management systems (QMS), published by the International Organization for Standardization (ISO). It provides a framework that organizations of any size can follow to ensure they consistently meet customer and regulatory requirements while continuously improving their processes.

Key Principles of ISO 9001

ISO 9001 is based on seven quality management principles:

- Customer focus – Meeting customer needs and enhancing satisfaction.

- Leadership – Ensuring leaders establish a clear vision and direction.

- Engagement of people – Involving employees at all levels in quality management.

- Process approach – Managing activities as interconnected processes for efficiency.

- Continuous improvement – Making ongoing efforts to improve performance.

- Evidence-based decision making – Using data and analysis to guide decisions.

- Relationship management – Managing relationships with suppliers and stakeholders for long-term success.

Main Requirements of ISO 9001

ISO 9001 defines a structured approach to quality management, focusing on:

- Context of the organization – Understanding internal and external factors that affect quality.

- Leadership – Defining responsibilities and ensuring commitment to quality.

- Planning – Identifying risks and opportunities and setting objectives.

- Support – Managing resources, competence, and communication effectively.

- Operation – Controlling processes to deliver consistent products/services.

- Performance evaluation – Monitoring, measuring, and analyzing results.

- Improvement – Addressing nonconformities and driving continuous improvement.

Benefits of ISO 9001 Certification

- Improved customer satisfaction and trust.

- Increased efficiency and process consistency.

- Better risk management and decision-making.

- Compliance with legal and regulatory requirements.

- Enhanced marketability and business opportunities.

Source: ChatGPT

The standard

ISO 9001:2015 Quality management systems — Requirements is a document of approximately 30 pages available from the national standards organization in each country. Only ISO 9001 is directly audited against for third-party assessment purposes.

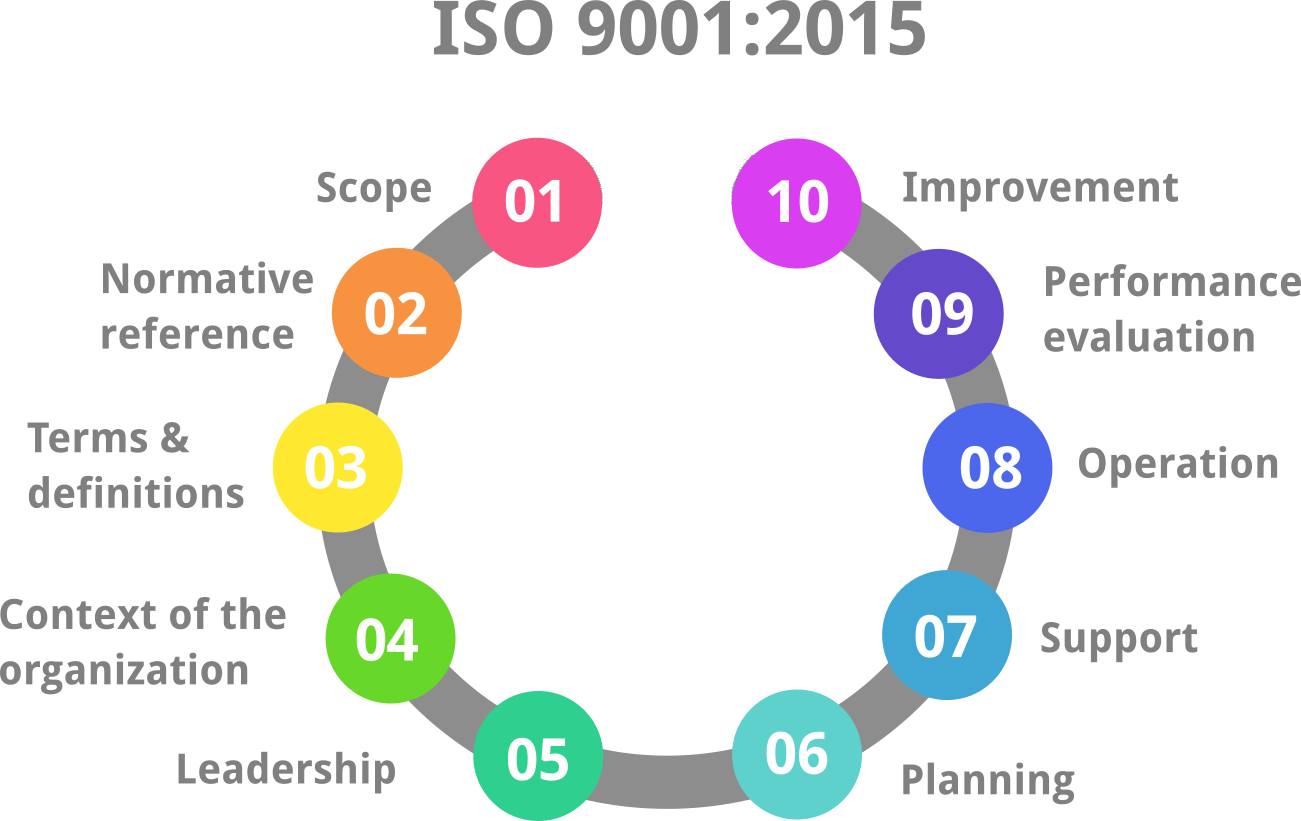

Contents of ISO 9001:2015 are as follows:

- Section 1: Scope

- Section 2: Normative references

- Section 3: Terms and definitions

- Section 4: Context of the organization

- Section 5: Leadership

- Section 6: Planning

- Section 7: Support

- Section 8: Operation

- Section 9: Performance evaluation

- Section 10: Continual Improvement

Essentially, the layout of the standard is similar to the previous ISO 9001:2008 standard in that it follows the Plan, Do, Check, Act cycle in a process-based approach but is now further encouraging this to have risk-based thinking (section 0.3.3 of the introduction). The purpose of the quality objectives is to determine the conformity of the requirements (customers and organizations), facilitate effective deployment, and improve the quality management system.

Before the certification body can issue or renew a certificate, the auditor must be satisfied that the company being assessed has implemented the requirements of sections 4 to 10. Sections 1 to 3 are not directly audited against, but because they provide context and definitions for the rest of the standard, not that of the organization, their contents must be taken into account.

The standard no longer specifies that the organization shall issue and maintain documented procedures, but ISO 9001:2015 requires the organization to document any other procedures required for its effective operation. The standard also requires the organization to issue and communicate a documented quality policy, a quality management system scope, and quality objectives. The standard no longer requires compliant organizations to issue a formal Quality Manual. The standard does require the retention of numerous records, as specified throughout the standard. New for the 2015 release is a requirement for an organization to assess risks and opportunities (section 6.1) and to determine internal and external issues relevant to its purpose and strategic direction (section 4.1). The organization must demonstrate how the standard's requirements are being met, while the external auditor's role is to determine the quality management system's effectiveness. More detailed interpretation and implementation examples are often sought by organizations seeking more information in what can be a very technical area.

Certification

The International Organization for Standardization (ISO) does not certify organizations themselves. Numerous certification bodies exist that audit organizations and issue ISO 9001 compliance certificates upon success. Although commonly referred to as "ISO 9000" certification, the actual standard to which an organization's quality management system can be certified is ISO 9001:2015 (ISO 9001:2008 expired around September 2018). Many countries have formed accreditation bodies to authorize ("accredit") the certification bodies. Both the accreditation bodies and the certification bodies charge fees for their services. The various accreditation bodies have mutual agreements with each other to ensure that certificates issued by one of the accredited certification bodies (CB) are accepted worldwide. Certification bodies themselves operate under another quality standard, ISO/IEC 17021, while accreditation bodies operate under ISO/IEC 17011.

An organization applying for ISO 9001 certification is audited based on an extensive sample of its sites, functions, products, services, and processes. The auditor presents a list of problems (defined as "nonconformities", "observations", or "opportunities for improvement") to management. If there are no major nonconformities, the certification body issues a certificate. Where major nonconformities are identified, the organization presents an improvement plan to the certification body (e.g., corrective action reports showing how the problems will be resolved); once the certification body is satisfied that the organization has carried out sufficient corrective action, it issues a certificate. The certificate is limited by a particular scope (e.g., production of golf balls) and displays the addresses to which the certificate refers.

An ISO 9001 certificate is not a once-and-for-all award but must be renewed, in accordance with the requirements of ISO 17021, at regular intervals recommended by the certification body, usually once every three years. There are no grades of competence within ISO 9001: either a company is certified (meaning that it is committed to the method and model of quality management described in the standard) or it is not. In this respect, ISO 9001 certification contrasts with measurement-based quality systems.

Source: Wikipedia